Folding Carton

OUR FOLDING CARTON SYSTEMS ARE DESIGNED FOR EFFICIENT PNEUMATIC CONVEYING

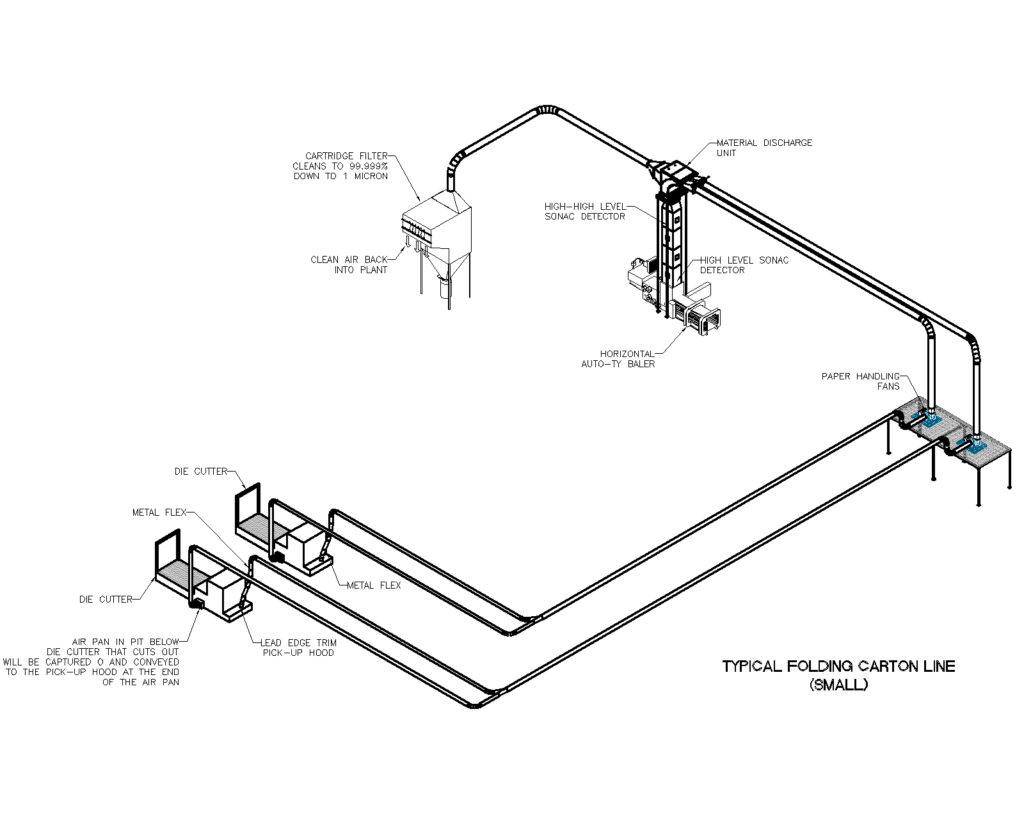

TAKE A LOOK AT THE ILLUSTRATION AS IT SHOWS A TYPICAL FOLDING CARTON SCRAP SYSTEM.

This utilizes an independent fan system for capturing and conveying the scrap being produced by each die cutter. By using independent fan systems and in-line diverter valves, it will be possible to run different grades on each production machine while preserving bale quality, which will yield higher returns when selling the bales.

COLLECTING THE CUT OUTS

For collecting the “cuts outs” and lead edge trim or skeletons being produced, a single fan system will be used. Initially, the cut outs will be captured on a collection conveyor or air pan placed underneath the machine. This will be used for directing the scrap from underneath the machine to a point at which it can be captured. The lead edge trim will be captured similarly as it exits the machine on the lead edge conveyor.

COLLECTED SCRAP IS CONVEYED TO A SEPARATOR SYSTEM FOR BALING

Once captured using the respective hoods, the collected scrap will be merged into a single line and conveyed together to a separator system for baling. If it is elected to implement a bale segregation system, diverter valves will be used to divert the scrap to the appropriate separator and baling system depending on grade.

VALVES AND SEPARATOR / BALING SYSTEMS

The number of valves and separator/baling systems will depend on the amount of grades required to be separated. Regardless of the amount of systems being used, all of the conveying air will be directed to a filter for cleaning and then returned to the facility or discharged to the atmosphere.

TYPICAL FOLDING CARTON LINE-SMALL ISO

IN THE PAST, WE HAVE INSTALLED THESE COMPLETE SEPARATOR AND BALING SYSTEMS UNDERNEATH A 19′ ROOF LINE.

ASK THE AIR SYSTEMS DESIGN TEAM ABOUT FOLDING CARTON SYSTEMS.