Printing – Retail

RETAIL PRINTING TRIM AND SCRAP HANDLING

IN PNEUMATIC CONVEYING SYSTEMS

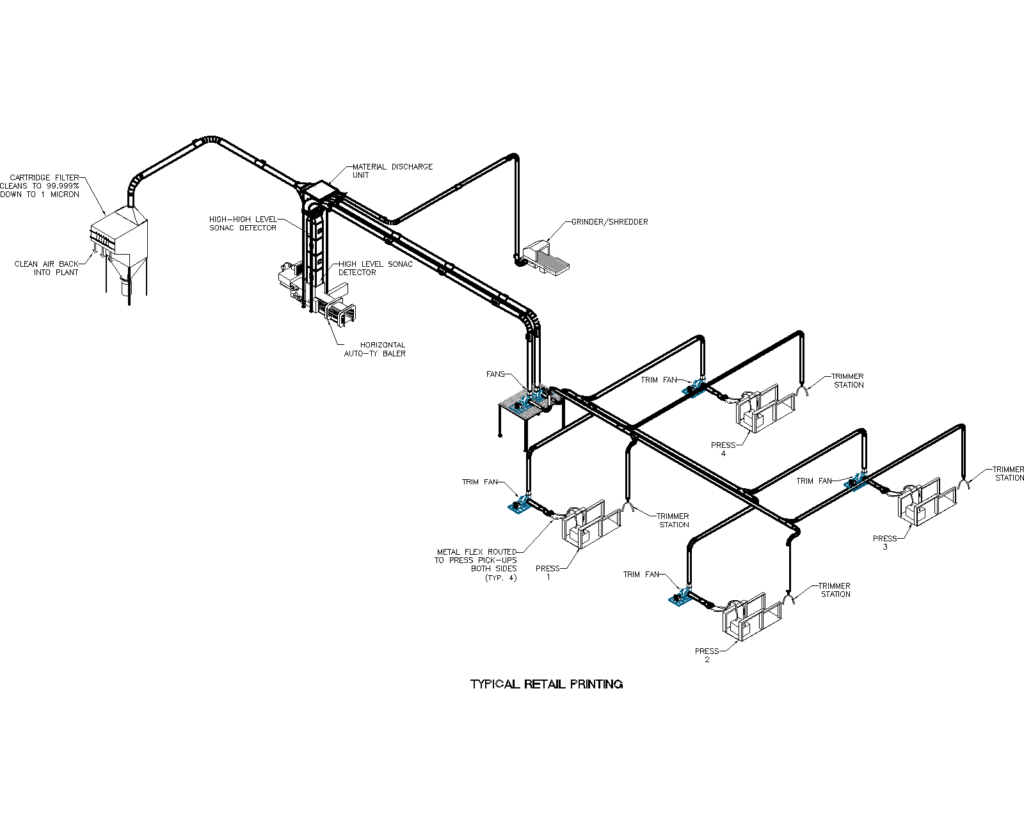

This illustration shows a typical Trim System for handling the trim and scrap being produced in a Retail Printing facility.

When designing the system, the trim and scrap being produced by the Presses, Portable Trimmers and Shredder have to be considered. These three (3) different areas are handled individually and therefore the number of fan systems required is dependent upon the number of presses.

TRIM

For trim handling generated by the Presses, individual fan systems are used having a single fan system dedicated to each Press. These fan systems are generally small in size and are located along side the Press. Once the trim ribbons have been captured, they are conveyed back to a separator system for baling. Since each fan system is dedicated to its own press, they may be turned off thus conserving energy while the press is not running.

RETAIL PRINTING TRIM SYSTEM ILLUSTRATION

FOR HANDLING THE TRIM BEING GENERATED BY THE PORTABLE TRIMMERS, A SINGLE FAN SYSTEM WILL BE USED.

It will utilize approximately eight (8) suction drops located throughout the facility. The number of these drops will be dependent on the number of presses being used. Each drop will utilize a flexible line for connecting to the portable trimmers (Gammiliers) placed at the end of the Presses. The flexible duct will allow for easily moving the trimmer at the end of sets so that it can be brought to another press where it can utilize another suction drop for conveying purposes. Once the trim has been captured from the trimmers it will be conveyed to a separating system for baling. Each pickup will be accessible at anytime the fan is running. Energy saving designs using cutoff gates (Manual and Automated) can be offered allowing only a select number of locations to be accessible at one time. This reduces the amount of air required thus reducing horsepower and the overall size of the system.

ASK THE AIR SYSTEMS DESIGN TEAM ABOUT RETAIL PRINTING, TRIM HANDLING AND SCRAP HANDLING SYSTEMS.

SHREDDER SYSTEM

For handling the larger waste products being produced a shredder system is generally provided. It is located in the baling area and utilizes its own fan system for conveying purposes. Once the shredded waste is captured it will be conveyed to a separator system for baling.

FILTERING SYSTEM

A filtering system is also utilized for cleaning the dust laden conveying air being used in both the trim fan system and the shredder fan system. Once the filter has removed the dust from the air stream, the clean air will be directed back into the facility or discharged to the atmosphere. The dust, meanwhile, will be collected in drums for further disposal.