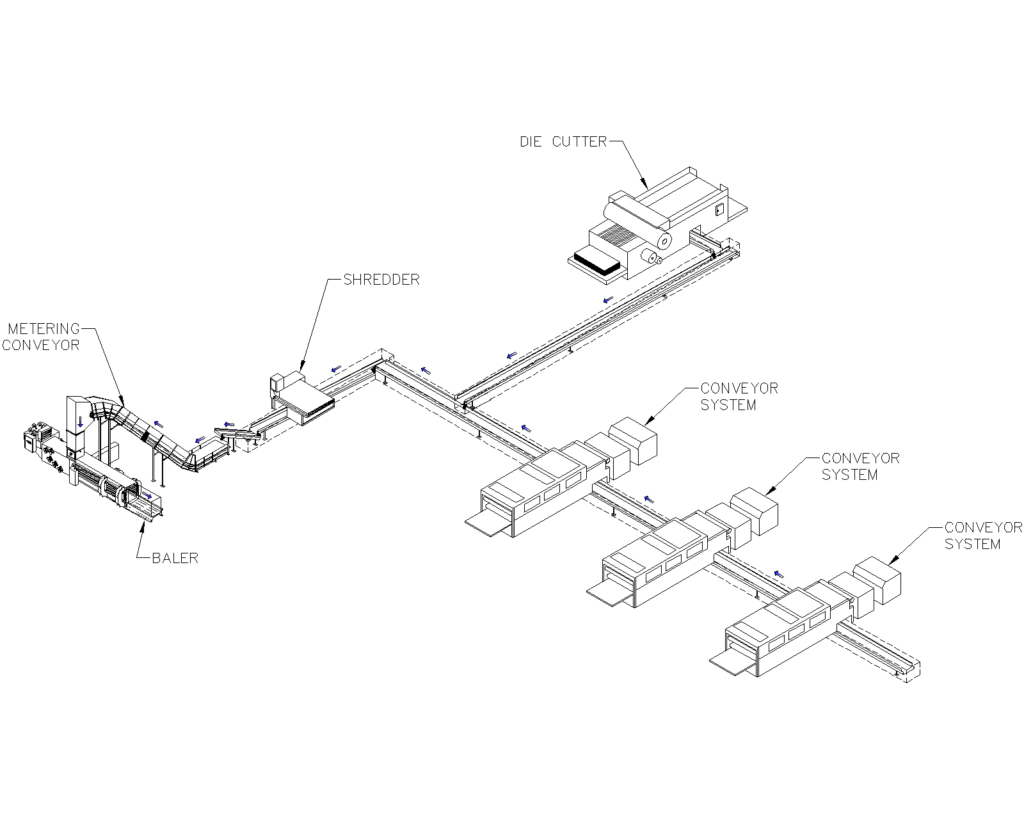

Corrugated/Conveyor

Corrugated Conveyors in Lieu of Pneumatic System Design

THIS NEW CORRUGATED CONVEYOR SYSTEM WAS INSTALLED BY AIR SYSTEMS DESIGN AND FEATURES UNDERGROUND SLIDER BED CONVEYORS WITH A BALEMASTER OPEN-END BALER.

THE OWNERS OF THIS SYSTEM HAD AIR SYSTEMS DESIGN, INC., DESIGN THE CORRUGATED CONVEYOR SYSTEM WITH PLENTY OF ROOM TO GROW.

While they do not yet require 8000 pounds per hour capacity, they had the foresight to create a system that will handle their anticipated capacity.

THIS SYSTEM FEATURES UNDERGROUND SLIDER BED CONVEYORS THAT ARE USED IN A STRAIGHT LINE PIT OR TRENCH.

An incline conveyor brings the material up and out into the open end baler. Designing the conveyor system this way yields a lot of savings, not just in the horsepower used, but if air was used in this type of conveying systems, a filter system would also need to be used which would result in a higher maintenance and capital cost.

WE KEPT THE SYSTEM EFFICIENT WITH 30 HORSEPOWER

If the same installation used a 270 HP versus the 30 horsepower we employed, the corrugator system would need to blow air into a cyclone and require a filter with the air coming back into the plant. The approximate cost to process this, including replacement filters and compressed air is very expensive, possibly $50,000 a year.

HERE IS THE BALEMASTER OPEN-END BALER WE INSTALLED WITH AN AUTO TIER.

This particular baler has an 8 inch cylinder and 30 horsepower. A cylinder, of 6 or 7 inches would have made loose bales. We are using a 40 inch feed chute which is a larger one well suited for this installation.

VIEW THE CORRUGATED CONVEYOR ILLUSTRATION BELOW