Tissue

TISSUE, TOWEL & NAPKINS, FACIAL WASTE AND BROKE HANDLING

EVERY MANUFACTURER IN THIS LINE OF BUSINESS HAS A DIFFERENT OPERATION THAN THEIR COMPETITORS.

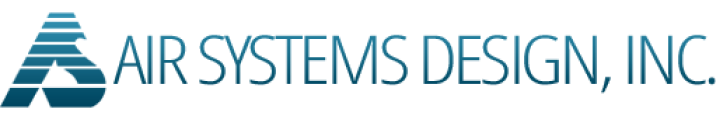

We have found when handling rolls and cookies from a log saw that a single system can be utilized and can handle up to six (6) log saws on a sequenced basis. Each drop from the log saw is a hopper with a gate arrangement in the hopper. The cookies and/or rolls accumulate on top of the gate until the gate is opened, dropping its accumulation of cookies into an airstream in a large duct and conveying some into a pulper or baler. This is done on a sequenced basis and the system will bypass any log saw not operating. If only one (1) is operating, it will stay on that unit continuously.

IN ADDITION TO THE “COOKIES” (OR NUBBINS AS THEY MAY SOMETIMES BE CALLED), YOU ALSO HAVE ROLL SLAB OR CORE SLAB THAT MUST ALSO BE TAKEN CARE OF.

Some roll slabs can weigh up to 300 lbs. so it is important to have a shredder located near the winder. The shredder should have a belt infeed. The slab can be pulled over to the shredder and one end of the slab can be placed on the belt and held down by hand, so the belt can pull the slab up the belt conveyor and fed into the shredder. The shredder should also have a compression section, which compresses the slab to be fed into the shredder. The air system should be sized to handle the loading conditions.

VIEW ONE OF OUR LATEST INSTALLED WET SCRUBBERS FOR A CLIENT’S TISSUE SYSTEM BELOW.

The conveying air is removed from the separator (with only a slight pressure) so there is minimal dust-laden air going into the pulper or baler. The baler must be sized for the maximum volume to be sure that the material will not back up into the separator. Since the product has a low density, each system must have several feet of baler chute. This will need to be designed per each system.

WHEN THERE ARE ONLY TWO (2) OR THREE (3) WINDERS AND SAWS IN A LOCATION WITH NO ROOM FOR FUTURE EQUIPMENT, A DIRECT PICK UP CAN BE PROVIDED AND DESIGNED TO MEET MATERIAL SPECIFICATIONS (DIAMETER, WEIGHT, AND VOLUME).

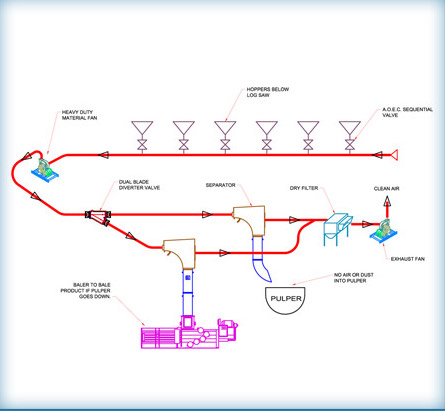

If the winders are in a paper mill and the broke is going to the pulper, a by-pass can be provided in the event the pulper must go down.

The broke box can be replaced with a baler if so required.

ASK THE AIR SYSTEMS DESIGN TEAM ABOUT OUR TISSUE, TOWEL & NAPKINS, FACIAL WASTE AND BROKE HANDLING SYSTEMS.

TISSUE SYSTEM GALLERY